Carbon fiber cutting machine: fast, clean, precise cutting

Test the SM-322-TA for industrial cutting of prepreg carbon fiber

Plug & Play cutting technology

Transform your machine in less than a minute

Over 20 years of experience

In the design and construction of semi-automatic machines for cutting technical fabrics and industrial materials

Pre and post sales Made in Italy

Machines made in Italy. Worldwide pre and post sales assistance

Carbon fiber, the material of the future and the cutting challenge

We often hear about carbon composite as the material of the future: high performance applied to various sectors. However, it would be more correct to talk about carbon fiber, a reinforcement widely used in the world of composite materials.

Carbon fiber-based composites are used in the production of various objects: bicycles and their components, fishing rods, but also medical prostheses and various components of aircraft and automobiles.

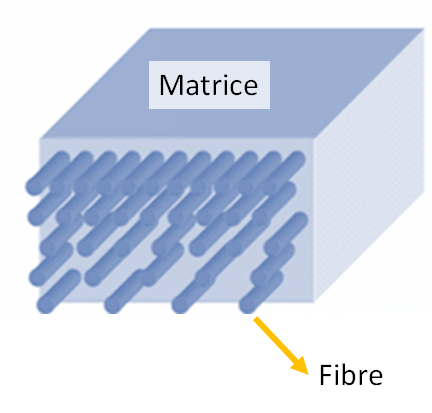

Carbon fiber is a material composed mainly of two components, also known as phases:

- a matrix, generally a resin

- a reinforcing material, which in this case consists of carbon fibers

Carbon fiber is generally impregnated with epoxy resin, which serves to hold the carbon threads together, transfer stress to them, protect them from external agents or accidental impacts, and give the material uniformity.

Application fields

Is it your industry?

If you are looking for a plotter for cutting carbon fiber, discover our cutting solution: SM-322-TA

Cutting Prepreg Carbon Fiber

Pre-impregnated carbon is a semi-finished product whose fibers are already impregnated with resin in the correct proportions. This (the constant matrix/fiber ratio) guarantees an essential requirement for achieving a repeatable process.

Automatic cutting is performed using semi-automatic CNC machines, better known as cutting tables or plotters.

Thanks to the use of special tools, chosen according to the specific characteristics of the pre-impregnated carbon to be cut, an intuitive and user-friendly HMI, and programs that optimize cutting by minimizing waste, it is possible to cut continuously to maintain or increase production rates.

DID YOU KNOW...

- Carbon fiber is about four times lighter than steel and about four times stronger.

- Carbon fibers are 10 times thinner than a human hair (a single strand is cylindrical in shape and measures 5-8 μm in diameter).

- To further increase strength, individual carbon fibers are combined into woven strands.

Different cutting technologies: blade, ultrasonic or laser

When it comes to cutting pre-impregnated carbon, it is always necessary to take into account the specific characteristics of the material, as well as the processes, requirements, volumes, production times, and field of application.

There is no universal technology for cutting carbon fiber; each decision must be evaluated based on various factors with the support of industry experts.

As far as automatic cutting is concerned, there are several technologies available on the market: blade cutting, ultrasonic cutting, and laser cutting. Each of these will give a different result in terms of cutting. Let’s compare them.

| Features | BLADE CUTTING | ULTRASONIC CUTTING | LASER CUTTING |

|---|---|---|---|

| Cutting precision | High | High | High |

| Edges Cut | Precise, clean | Precise, clean | Yellowed, burned |

| Cutting Speed | High | High | Depends on the thickness |

| Emissions | No | No | Yes |

| Air Treatment | Not needed | Not needed | Needed |

| Safety device mask | Not needed | Not needed | Needed |

| Versatility | High | Medium | Limited to low thickness |

Cutting plotter for carbon fiber

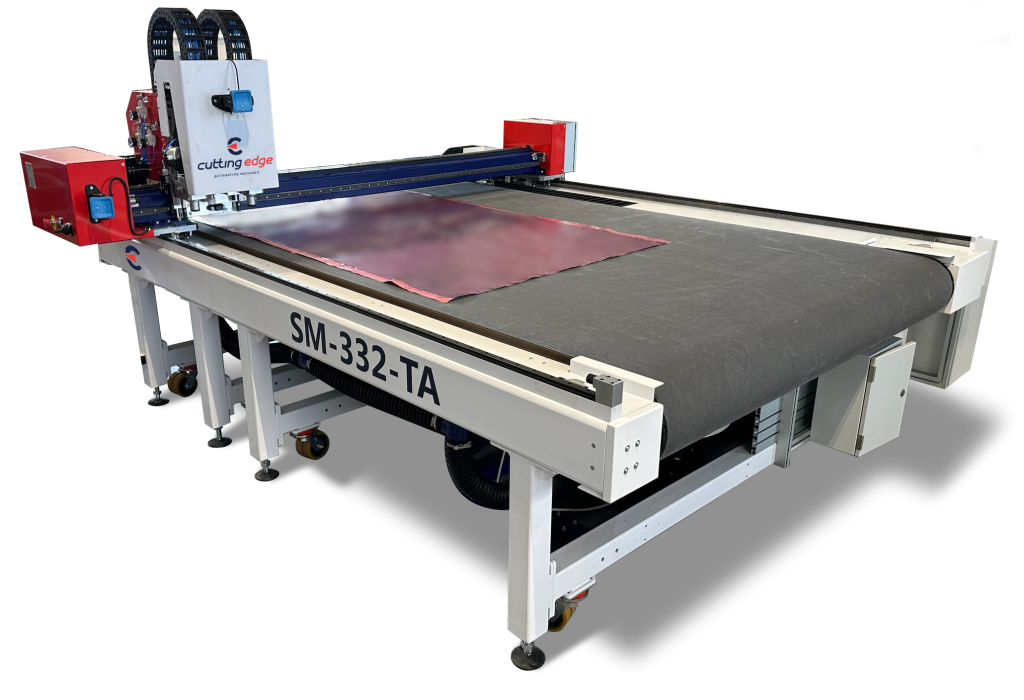

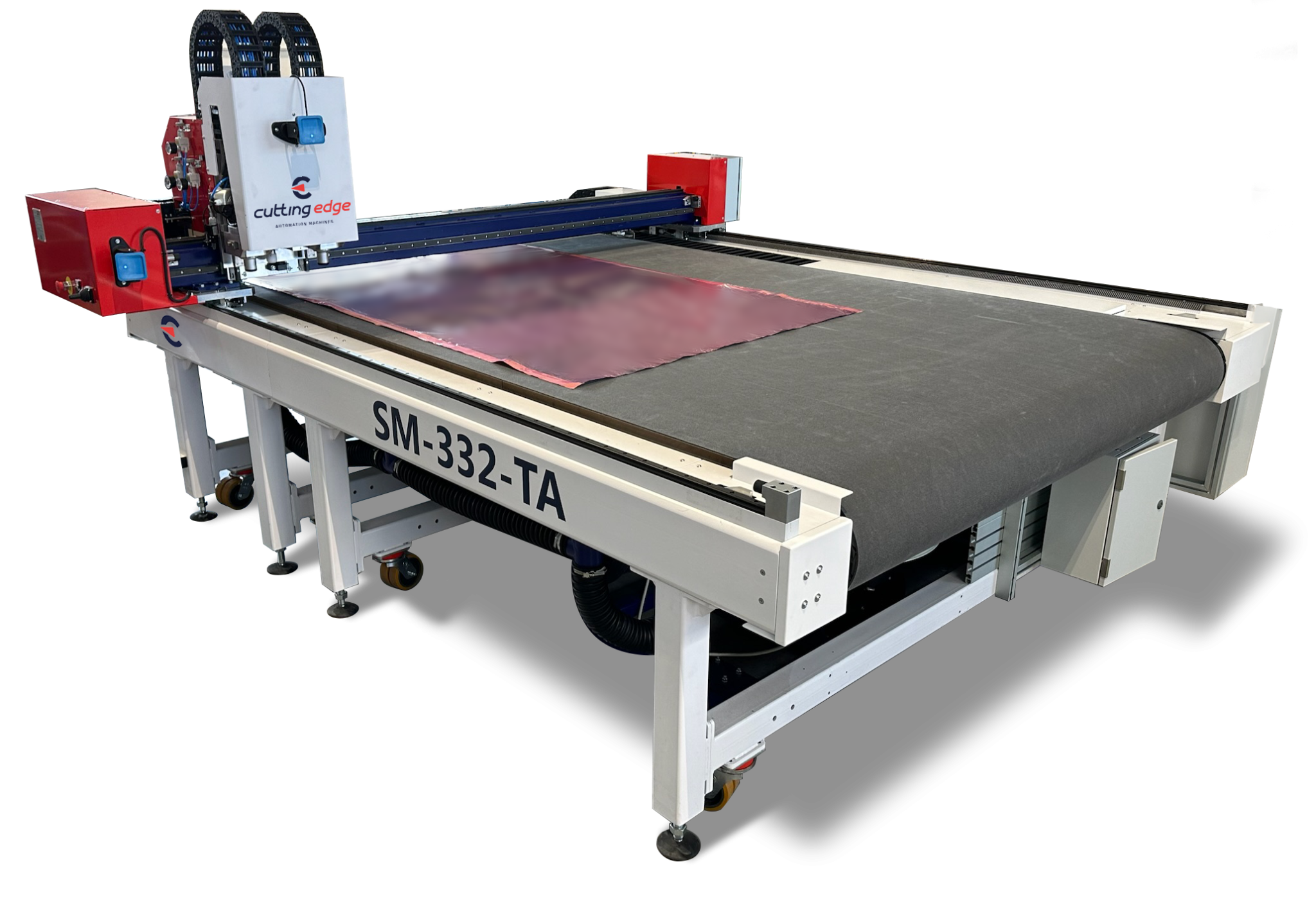

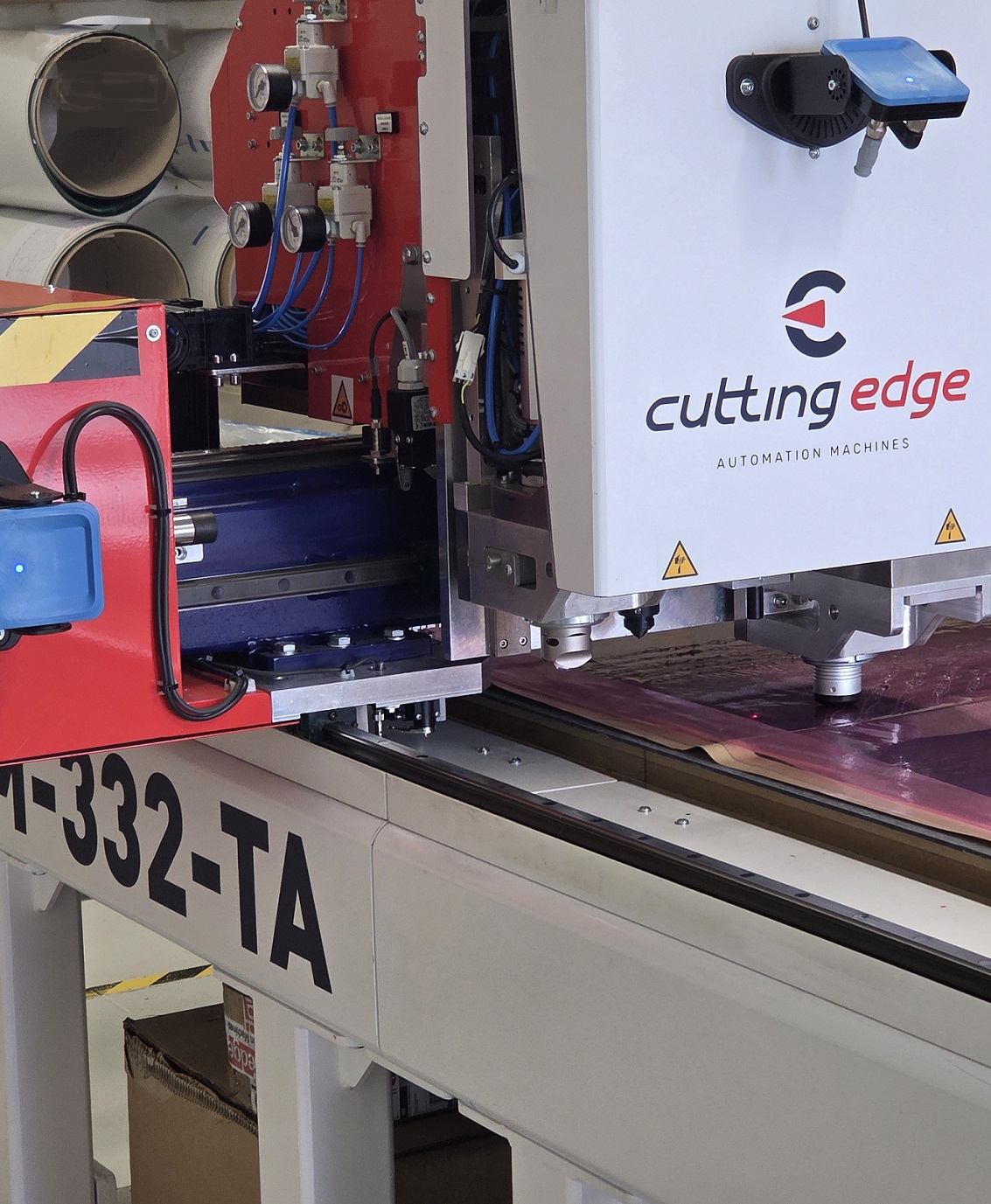

With over 20 years of experience in designing semi-automatic machines for cutting technical fabrics and industrial materials, Cutting Edge Automation Machines has concentrated its technical skills, know-how, and field experience into the SM-332-TA. This plotter offers customers a wide range of solutions for cutting carbon fiber and other composite materials.

The SM-332-TA is a reliable cutting machine with a robust structure. Optimized for cutting composite materials, it also offers a high degree of customization and versatility to meet the individual needs of each of our customers.

- Cutting speed up to 90 m/min.

- Acceleration up to 1G

- Accuracy +/- 0.1 mm

- Repeatability +/- 0.05 mm

- Available in various sizes

- Double housing for interchangeable tools

- Laser pointer

- Marker holder

- Housing for two punches

- Industrial conveyor belt

- Cut material discharge area

- Triple system for transporting fabric (presser bar, clamps, and conveyor belt)

- Marker

- Laser pointer for determining dynamic zero

- Drag knife

- Vibrating knife

- Non-motorized rotary blade

- Motorized rotary blade

- Kiss-cut

- V-cut

- Vibrating V-cut

- Milling tool

- Punching tool

- Creasing tool

- Ultrasonic blade

- EasyWork Xtreme

- Automatic nesting

- Splitbox

- Barcode reading

- Easy Production Management System (EPMS)

- Easy Data Monitoring System

Download the brochure via email

5 Reasons for choosing the SM-332-TA

Discover our carbon fiber cutting machine: SM-332-TA.

Come and test its performance with a dedicated demo.

- Precise, clean and fast cuts

- Plug&Play tool exchange system

- Multiple cutting technologies available

- Robust machine with a solid industrial structure

- Innovative safety systems with sophisticated radar sensors

And after the purchase?

Our work does not end with the delivery and installation of the machine, because our customers are first and foremost business partners, and contributing to the success of their products is one of our main objectives.

- Training

- On-demand free consulting

- Spare parts management

- Periodic maintenance options

- Interventions at the customer's site in Italy and abroad

Customization

Cutting carbon fiber requires careful evaluation of the specific type of material to be processed (and its components), production requirements, and the type of final application.

This analysis will lead to the configuration of the most suitable machine.

Thanks to the wide choice of technologies, tools, and accessories, the SM-332-TA offers solutions that perfectly meet customer needs.

Do you want to learn more?

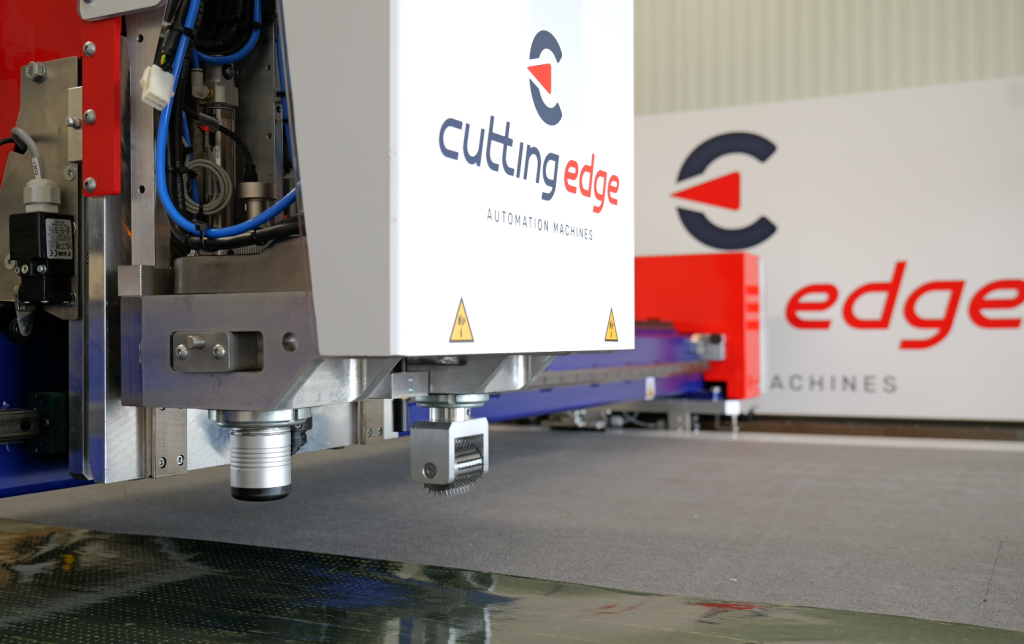

Plug & Play

Our cutting machine has double tool holders and can accommodate up to two tools at the same time, in addition to the marker, laser pointer, and the option of having two punches tools.

The great advantage offered by the SM-332-TA is the quick change of cutting tools: the tool can be replaced in just a few steps, all in less than 1 minute.

Safety Systems

The SM-332-TA is equipped with a sophisticated safety system designed to protect the operator. Radar sensors located on the bridge and cutting head ensure maximum safety during operation.

When an obstacle is detected, the machine automatically stops at a preset safety distance of 500 mm (radar located on the head) or 800 mm (radar located on the deck).

Versatility and reliability

The SM-332-TA was created as a highly flexible machine, designed to maximize production efficiency and meet a wide range of cutting requirements.

Years of experience and careful design have led to the development of a machine with a robust structure, high-quality components, and high performance.

Fill the form to have more details

- Italian Company

- Free online demo

- +25 years of experience

Contact Us

Cutting Edge Automation Machines

Cutting Edge Automation Machines, originally operating as SMRE SpA, has been active in the field of automation machine manufacturing for 25 years.

The company designs and manufactures high-tech production solutions for cutting, welding, and sewing technical, industrial, composite, and PVC fabrics.

Based in Umbertide (Perugia), it is a well-established company in its sector and has delivered more than 2,000 machines to over 50 countries to date.

Where we are

Piazza Antonio Meucci, 1 Loc. Montecastello 06019 Umbertide (PG) - Italia

Contac Us

info@cuttingedgeam.com

sales@cuttingedgeam.com

+39 075 930 6500